1 / 3

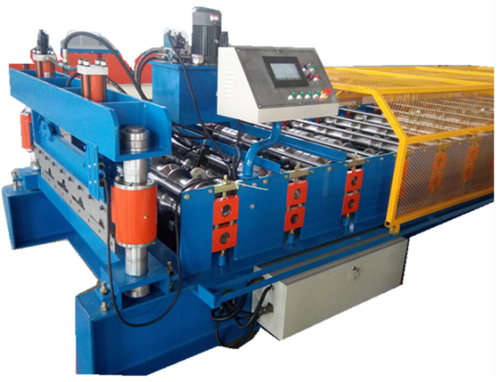

Reputable Color Steel Roof Rollformer on Sale

| Model No. : | ZT-005-238 |

|---|---|

| Brand Name : | zhongtuo |

| Main Motor Power : | 7.5kw |

Cangzhou, Hebei, China

- Производитель

- OEM -сервис

- Сертификация платформы

- Онлайн -выставка

- видео

Описание продукта

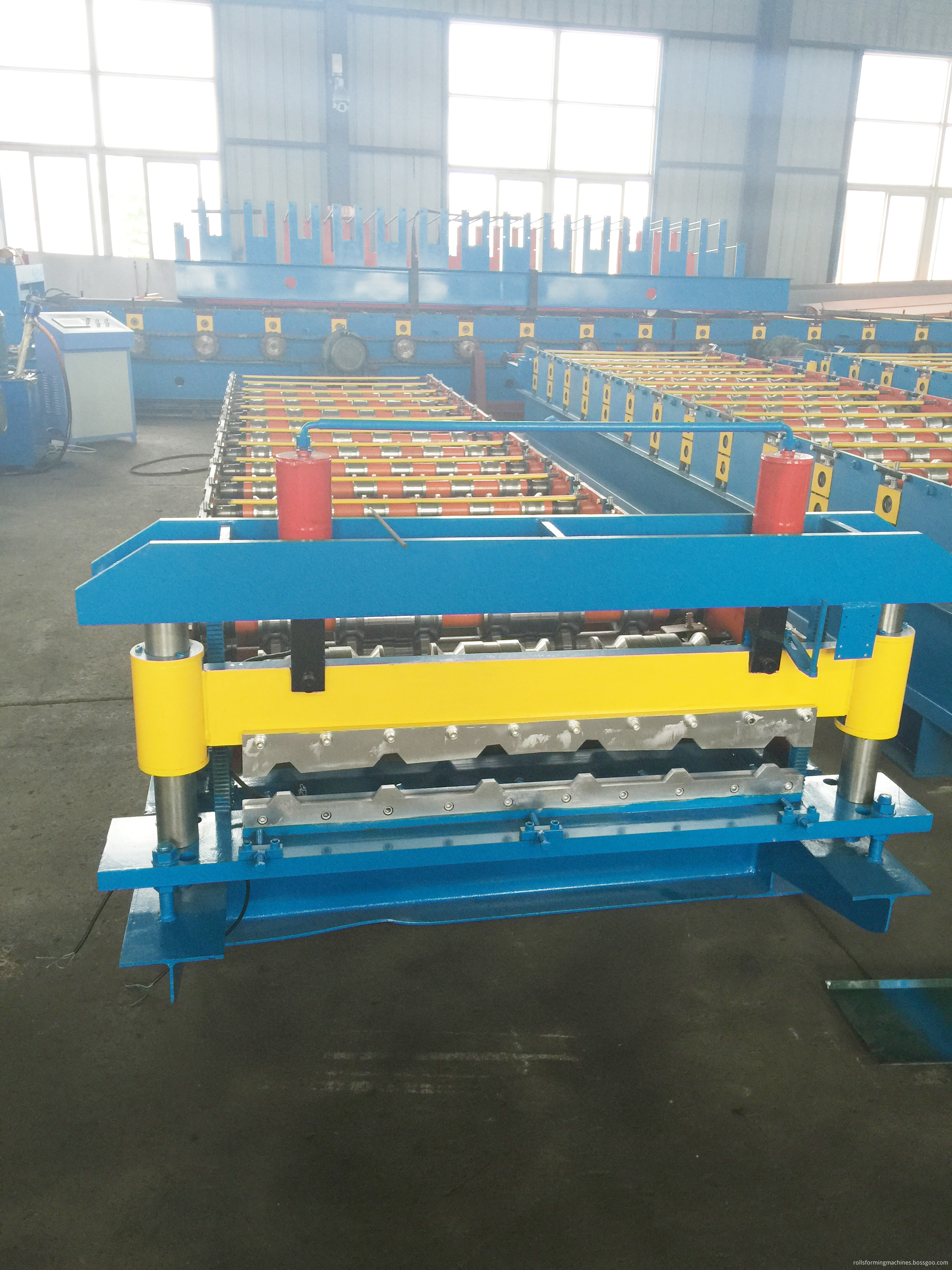

Reputable Color Steel Roof Rollformer on Sale

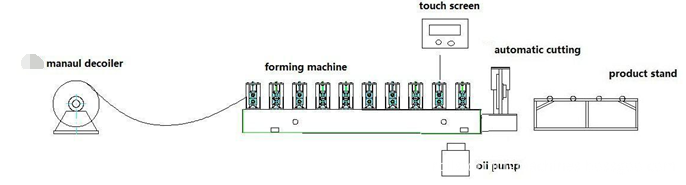

1.Processing flow diagram of machine

Manual decoiler→ Feeding material into machine →Roll forming machine →Measure length →Hydraulic cutting →Finished Products

|

configurations |

manual decoiler, guiding platform, main machine of roll forming, cutting device, electric motor, hydraulic station, Delta PLC control system, run out table |

|

|

Material (This material is a little hard than normal material , so the machine need to be made according this material) |

Minimum Thickness |

0.3-0.8 mm |

|

Max Thickness |

1.0 mm |

|

|

effective width |

1000 mm |

|

|

Feeding width |

1200 mm |

|

|

Hydraulic Uncoiler |

Coil inner diameter |

450-550 mm |

|

Max coil out diameter |

1300 -1600 mm |

|

|

Max coil width |

1250 mm |

|

|

Carrying capacity |

5 T |

|

Entry Beach |

Put the raw material (steel plate) through the beach to manufacture and process, |

|

it can guarantee that the products are neat, parallel and everything is uniformity |

|

|

Please refer to the equipment regulation to know the function of locate dam board. |

|

Main machine |

Forming steps |

13 / 15 rollers |

|

Shaft diameter |

80mm |

|

|

Design type |

Middle Plate Structural |

|

|

roller material |

45# steel chrome plating chromium |

|

|

shaft material |

40 Cr steel |

|

|

Work speed |

8 m/min |

|

|

Transport |

By chain |

|

|

Power of main machine |

5.5 kw |

|

Type of cutting |

Hydraulic |

|

Cutting tolerance |

±1mm |

|

Cutter |

Gcr12 |

|

Cutter quantity |

2 set |

|

Working pressure |

40MPA |

|

Tile Pressing and Shearing Mechanism

|

Feature |

Ensure stability, precision and cutting speed |

|

Function |

Automatic cutting controlled by PLC. It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products. |

|

|

Material of blades |

Cr12 quenched |

|

|

Power supply |

hydraulic power |

|

|

Components |

It contains one set of blade, one hydraulic tank and one cutter machine. |

|

Hydraulic Station

|

Power |

5.5 kw |

|

Hydraulic oil |

46# |

|

|

Components |

The system includes a set of hydraulic tank, a set of hydraulic oil pump, 2 hydraulic pipes. And 1 sets of electromagnetism valves. |

|

Electric Control System |

1.Adopted PLC, frequency converter, Delta from Taiwan to ensure high speed with stability, precision and lifetime. If you need, we can change it other brand or little computer type for touching screen. |

|

Counter |

One counter gauges length, pulses, and decides length.Omron encoder for length measurement |

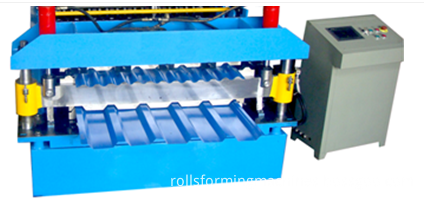

This glazed tile roll forming machine is well designed and full automaticly. Glazed tile roll forming machine can produce the steel glazed tile roofing sheet. this glazed tile steel roofing sheet is popular in Europe and other countries.

please check below new finished machine pictures:

ZTRFM has been dedicating to roll forming technologies for over 2 decades and now boasts strong experience, capabilities, innovative thinking and roll forming expertise to provide perfect roll forming solutions to our clients. At ZTRFM, we can help build a better future for you and your customer.

FAQ

1. IS AFTER SALES SERVICE AVAILABLE?

Yes, we offer 7x 24hours online support and our engineers can work oversea to help.

2. HOW CAN I GET TO YOUR FACTORY?

a. First fly to Beijing airport and then go from Beijing Nan to Cangzhou Xi (1 hour) by high speed train . Then we can pick you up at the railway station.

b. First fly to Shanghai Airport and then go from Shanghai Hongqiao to Cangzhou Xi(4.5 hours) by high speed train. Then we can pick you up at the railway station.

3. WHAT IF SOME PARTS BREAK?

We offer warranty of 12 months ,during which free spare parts are available if some parts of the machine break to be irreparable. Besides, we also offer whole life technical support which means we will still offer technical advice 1 year after your purchasing. We can discuss to help you out.

4. CAN YOU TAKE CHARGE OF TRANSPORT?

Yes, we have strong expertise in this area for years and you can trust us.

Cangzhou, Hebei, China

- Производитель

- OEM -сервис

- Сертификация платформы

- Онлайн -выставка

- видео

Отправьте запрос этому поставщику