1 / 4

Машина для глубокой печати на бумаге

| Model No. : | Asy-g6800 |

|---|---|

| Brand Name : | САНЛОНГ |

| place of origin : | China |

Wenzhou, Zhejiang, China

- Производитель

- Торговая компания

- OEM -сервис

- Поставщик золота

- Сертификация платформы

- Сертификация SGS

Описание продукта

Эта цена включает:

- Подходящий материал для печати: OPP, BOPP, CPP, PET, PVC, PE, нейлон, бумага, алюминиевая фольга и т. Д.

- Максимальная скорость печати 100-130 м / мин

( Это зависит от материала и диаметра пластины, чернил и режима работы )

- Система автоматического совмещения цветов, точность: ± 0,1 мм

- Автоматическое натяжение, управляемое программой ПЛК.

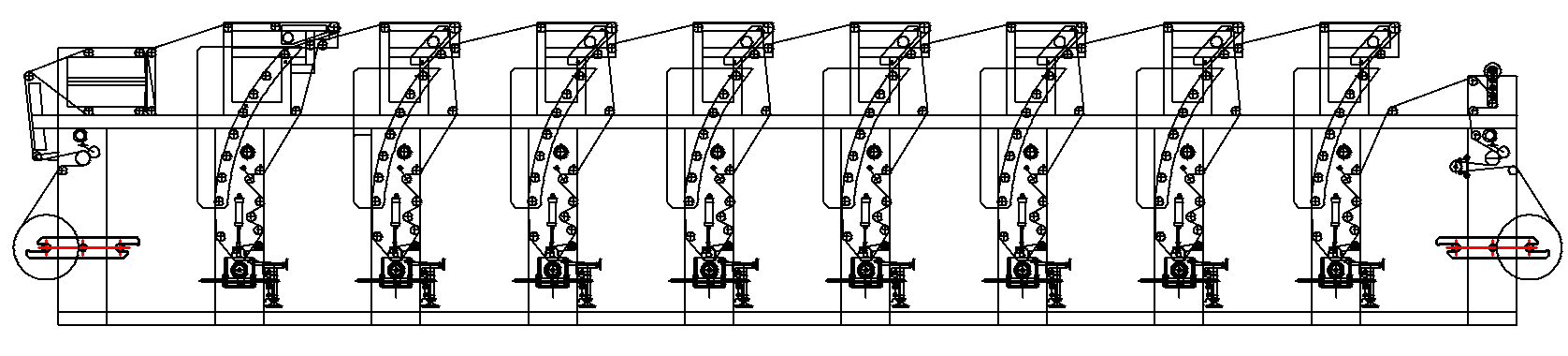

Чертеж для справки :

|

Main Technical Parameters(800 mm 8 color for reference) 1. Printing color:8 Colors 2. Printing material: Cellophane: 20-30um PET:12-60um BOPP:18-60um CPP:25-60um Nylon:15-50um HDPE、LLDPE:20-80um 3. Max printing width: 800mm 4. Max mechanical speed: 140m/min 5. Printing speed:100-130m/min(it depends on the feature of material and diameter of plate, ink and operation) 6. Vertical color register precision:±0.10mm 7. Diameter of printing cylinder:Ф120mm-Ф300mm 8. Max width of printing cylinder:850mm 9.Width of guide roller: 830mm 10.Inner width of machine: 1080mm 11.Diameter of unwinding and rewinding: Max Φ600mm 12. Power of main motor: 7.5KW 13. Rewinding adopts double-torque motor 14. Total power: 120KW(each color 15KW) 15. Total weight: 12000kg 16. Overall dimension(L·W·H):13500×2600×2800mm 17. Color:milk white(other colors options) 18.Cast iron frame: Daqiao, Taiwan |

|

|

|

1. Unwinding unit: 1.1 Reel unwind frame: (1).Tumbling dual-station, two unwind shafts controlled by two sets of magnetic powder brakes (2).Left and right adjustment of material:manually,adjustment ±20mm (3).Max diameter of unwind:Ф600mm (4).Auto tension controller: 1set Wenzhou (5).Range of tension: 3-25kg (6).Magnetic powder brake: 2.5kg 2sets Wenzhou (7).Air shaft of unwind&rewind:Ф74mm 1.2.Unwind traction (1)Structure:pneumatic compression type (2)Traction roller is driven separately by motor,power 2.2kw 1set (3)Low friction cylinder and swagging roller tension inspection system (4)Range of tension control 5-190kg |

|

|

|

2.Printing unit 2.1.Printing cylinder: (1).Left and right adjustment of printing cylinder:manually,adjustment±50mm (2).Gearbox:high precision gear transmission,adopts patent technique 2.2.Pressing roller: (1).Pressing:double-cylinder pressing and the pressing force can be adjusted according to requirements (2).Max pressing force:300kg (3).Specification of pressing:Ф130mm 2.3.Doctor blade: (1).Pressure of blade:adjustment pneumatically,pressing force can be adjusted according to requirements (2).Adjustment of blade:horizontal, vertical direction and angle of blade all can be adjusted by manual (3).Swing of blade:pneumatic back pressure moving blade ±2.5mm 2.4.Ink pan: (1).Ink to printing cylinder:immerse the printing cylinder directly to the ink (2).Vertical up&down of ink pan:hand wheel (3).Material of ink pan:Iron cast steel 2.5.Circulation of ink:motor ink pump or air separated circulation pump optional 2.6.Drying oven: (1).Structure:sealed oven,hot wind spreads fast with arc structure, fast drying and energy saving (2).Heating type:wing heating tube,external heating plus air back system (3).Power of heating:power of each color group 15 KW(each color) (4).Control of drying temperature:auto constant temperature control(each color),power of centrifugal fan 1.1KW (5).Each color adds cold wind box,power of centrifugal fan(each color)0.55KW (6).Oven height of the last color group adds more 200mm,good for ink drying 2.7.Guide rollers (1).Guide rollers:adopt aluminum alloy after anode oxidation processing and in balance |

|

|

|

3.Rewind unit: 3.1.Rewind traction (1).Structure:active pulling pneumatic compression type (2).Driving:torque motor 16N.M 1set 3.2.Rewind frame: (1).Structure:tumbling dual-station, two rewinding shafts driven by two torque motors (2).Core paper mounting:air shaft(Ф74mm) (3).Left and right adjustment of material:adjustment±20mm (4).Motor of rewinding: torque motor 25N.M 2sets (5).Diameter of rewinding: maxФ600mm 4.Vertical color registration:China brand color registration system(Kesai,Shangxi) (2).Suitable for printing speed:5-300m/min (3).Precision of printing: ±0.1mm (4).Main motor of vertical color registration(seven tunnels) 1set (5).Electronic sensor 7pcs 5.Supporting facilities:(arranged by user) (1).Power:three phases four wires air switch 380V 50Hz (2).Power cable |

Wenzhou, Zhejiang, China

- Производитель

- Торговая компания

- OEM -сервис

- Поставщик золота

- Сертификация платформы

- Сертификация SGS

Отправьте запрос этому поставщику