1 / 5

Chocolate Core Filled Snack Food Production Line

| Brand Name : | DARIN |

|---|---|

| Customized : | Customized |

Jinan, Shandong, China

- Производитель

- OEM -сервис

- Сертификация платформы

- Онлайн -выставка

- видео

Описание продукта

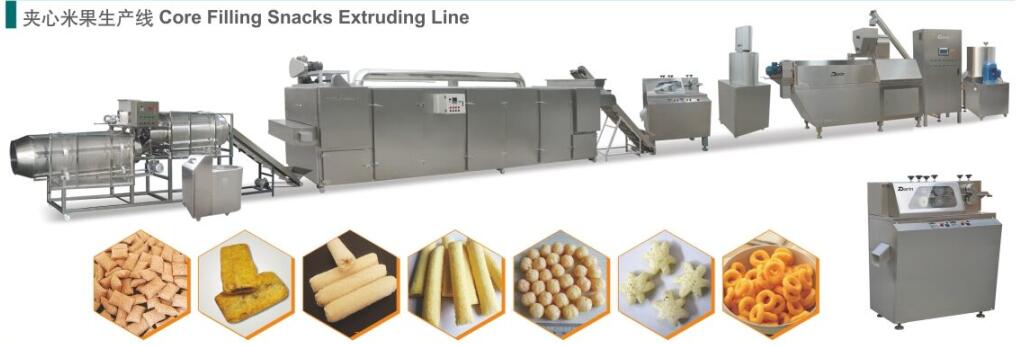

Chocolate Core Filled Snack Food Production Line

Instruction

Chocolate Core Filled Snack Food Production Line's temperature is precisely regulated through individual heating and cooling systems in each section of the extruder barrel.

Chocolate Core Filled Snack Food Production Line, after extrusion, snacks are conveyed by a pneumatic conveyor into the Multi-pass dryer. From the dryer the snacks fall into the continuous coating drum and receive the spices (flavors, salt, fat, cheese or other spices). After being seasoned, the snack is conveyed into automatic vertical packing machine.

Chocolate Cor Filled Snack Food Production Line is from feeding materials, extruding, core filling, shaping, drying, oil spraying to finish products are done once time automatic. We fill the gap of the first-class food produced with extruded & inflated technology. This processing line can produce all kinds of inflating foodstuffs, rice bread, core snacks, crackers, gruels, nutrients-flour, breakfast cereal and baby food and so on. The raw material can be maize rice and wheat flour.

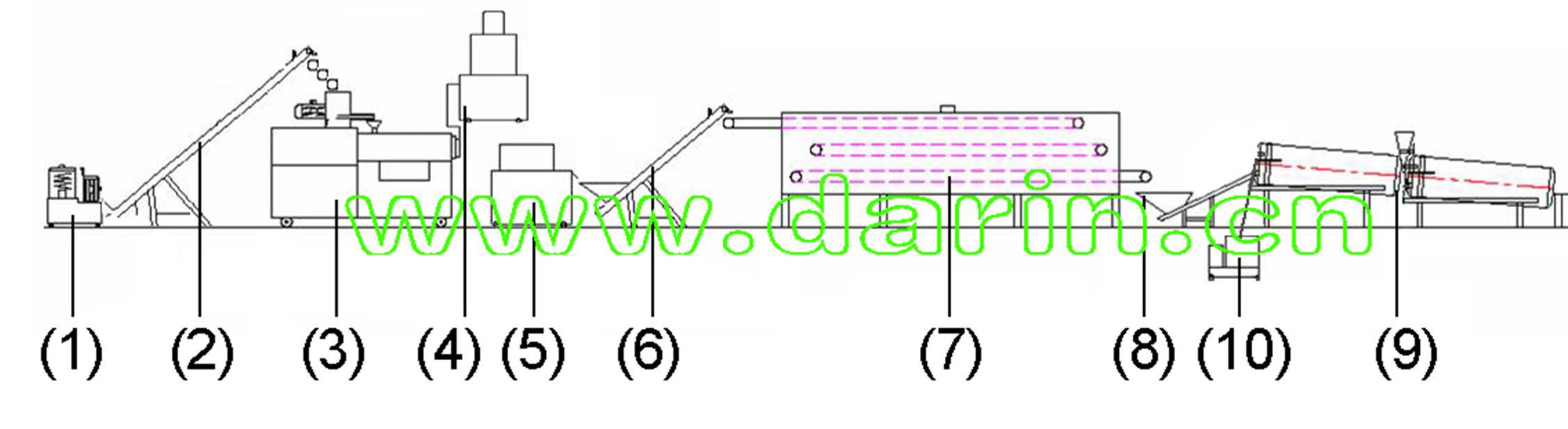

Flow

Mixer→ Screw conveyor → Extruding→ Core Filling→ Shaping → Roasting → Flavoring Coating → Cooling

Layout

Technical Parameters

| Model | DR-65 | DR-70 | DR-85 |

| Capacity | 120-150kg/hr | 200-250kg/hr | 300-400kg/hr |

| Power | 95kw | 140kw | 160kw |

| Dimension | 18 x 5 x 3m | 20 x 5 x 3m | 22 x 5 x 3m |

Why Choose Us?

1. Motors are from WEG, Brazil, which has 3-year world-wide guarantee or Siemens;

2. Electric parts are from ABB or Schneider, easy to find replacments at local market;

3. PLC and touch screen are from Siemens, Germany to realize easier operation and less labor quantity;

4. PLC and touch scrren controls whole processing line, not one or two single equipment;

5. While faults occurred, relevant information will be displayed on touch screen, easy to settle the problem;

6. Control cabinet has 24V safe voltage (not 220V), which could protect the operator even electric leakage occurred;

7. Three kinds of protectors to keep machine and operator safe: over-current protector, over-voltage protector and over-heat protector;

8. All the cover body, mesh belt and parts touching with materials or final products are made by stainless steel 304.

Machine picture

Clients from all over the world

Manufactured in DARIN

Key Equipment Show

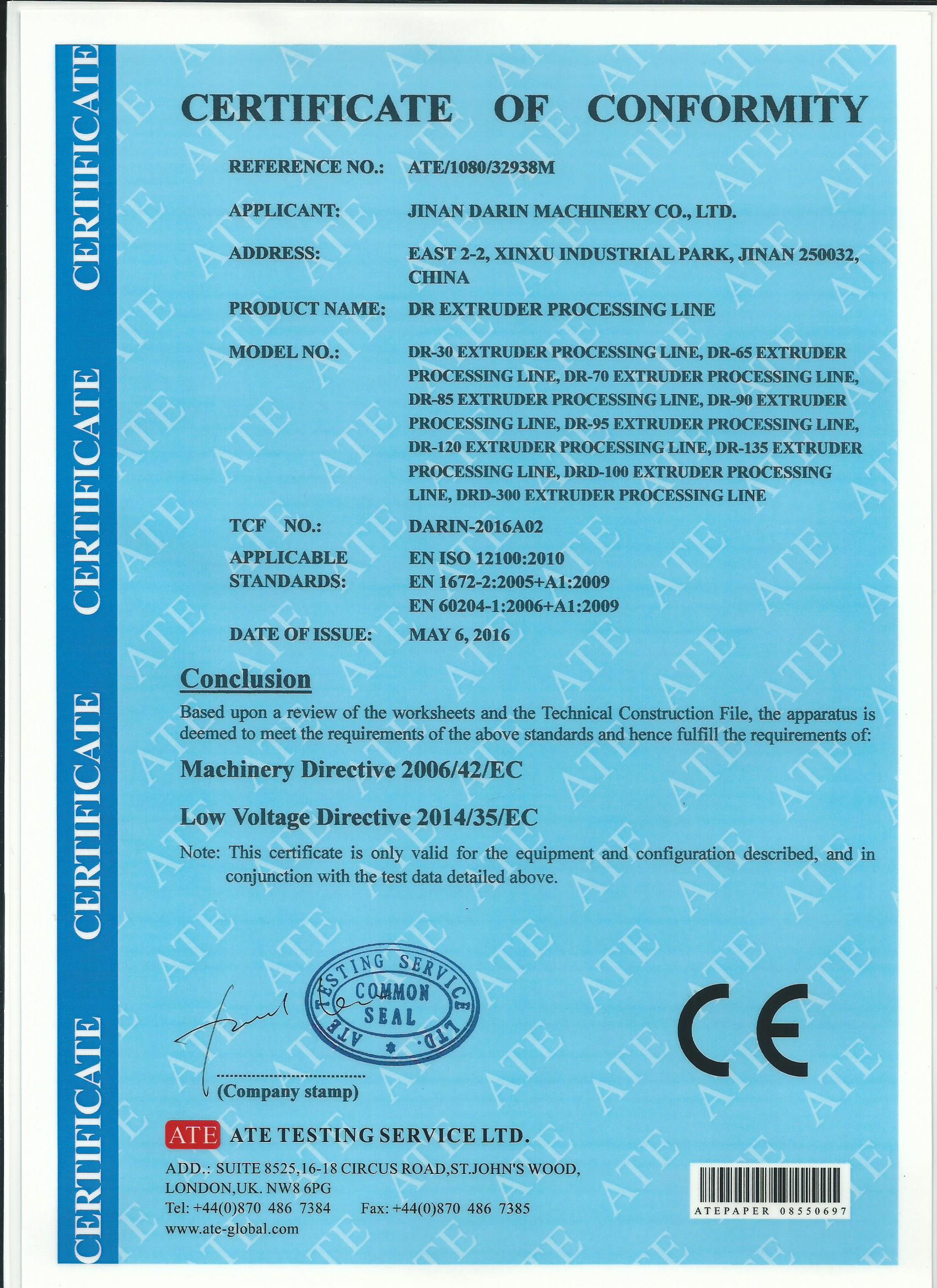

Certificate

Package & Shipping

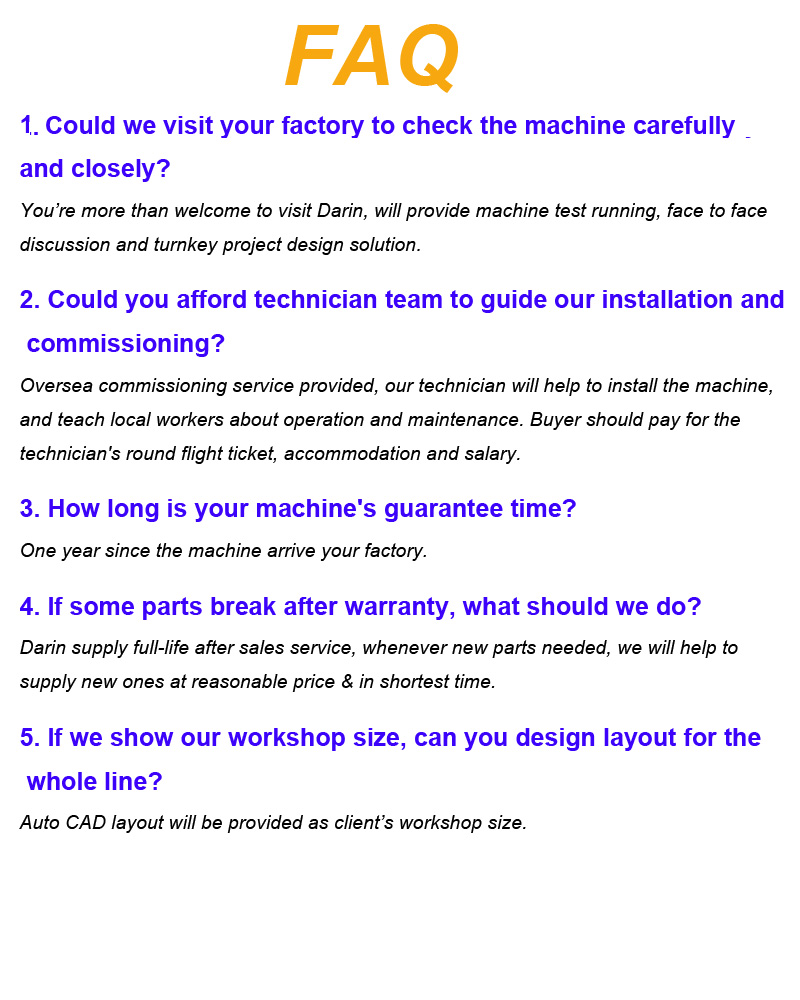

FAQ

Exhibition

Our factory

Contact

Jinan, Shandong, China

- Производитель

- OEM -сервис

- Сертификация платформы

- Онлайн -выставка

- видео

Отправьте запрос этому поставщику