1 / 1

Injection Molding Slider Mechanism

| Model No. : | 50X60X45 |

|---|---|

| Shaping Mode : | Injection Mould |

Описание продукта

Injection Molding Slider Mechanism

Determined to succeed together. Here at Hongzhun Technical Plastics, that`s what we aim to do and it applies equally to the relationships we build with our staff, suppliers and clients. We are growing through our fantastic customer service ethos and commitment to our employee engagement.

Hongzhun Technical Plastics is a family owned plastic injection moulding company, established in Shenzhen city in 1974. Together, our technical team provides years of combined experience in plastics, tooling and manufacture – and every day they apply it to innovating the plastic injection moulded products and components our clients need.

We have over 100 people in our team which includes highly trained moulding technicians, toolmakers, quality engineers and multi-skilled operatives.

Together they operate 16 injection moulding machines – ranging from 50t to 300t – operating 24 hours, 7 days a week.

We are ISO 9001-2008 Quality Management System accredited, and are working towards TS16949, the recognised quality standard in the automotive industry.

Description:

Process tolerance: +/-0.01mm

Manufacturing Lead time: 14 days

Delivery lead time: 3 days

Size: 50X60X45mm

Material: 1.2343

Hardness: 52+2 HRC

ISO 9001 certified

Mold components for injection mold

HS code: 84804100

Advantage:

- Quality: it is life of company. we have been working with our customer from USA and Europe for more than 10 years .

- Price/leadtime: it is power to develop the company, we can provide the best price with leadtime.

- Service/communication---it is keeping good relationship.

- We are interesting on making Auto mold, Home appliance and other plastic mold.

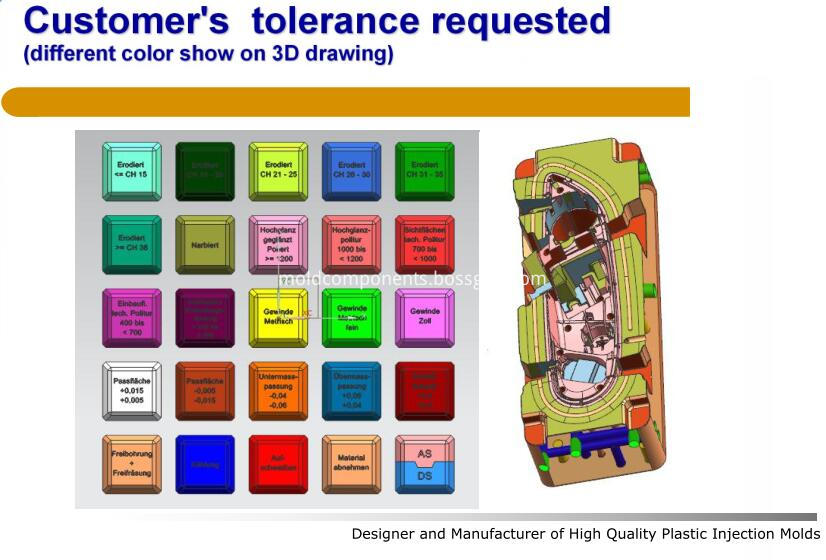

How can we control the quality

Component making standard

1,All components must be making according to customer`s request by different color shown on 3D drawing to keep the correct tolerance .

2,All components must inspect at every process(every step) by CMM machine .

3, All components must engrave by marking machine,not by hands.

4,All components must chamfer by machine, not by hands.

5,All components must to be done by high speed CNC, mirror EDM,slow wire cutting .

6,All components must be clean before shipping.

7,All components can`t welding before get the approved from customer.

8,All components can`t be any delay.

9,All components must provide steel certificate.

FAQ

Q. When can I get the price ?

A. We usually quote within 24 hours after we got your inquiry. If you are very urgent to get the price, please call us or tell us in your email so that we will regard your inquiry priority.Q. How can I get the accurate price ?

A.There are some basic specs we need to know for price calculate, that are: 3D drawings in STP,IGS,X-T format are avaialble, Please suggest us your quantity too.Q. Do you accept the OEM?

A. OEM is welcome. We can custom the good according to your design.Q. What is the shipping ?

A:By express(FedEx, UPS, DHL, TNT, EMS, etc...),By Air,by shipping.Q. How do i pay for the order?

A.The common payments are T/T(Telegraphic Transfer),western union ,Q.Ok, I've decided to go ahead with my project. How long will it take to get my parts?

A. It can take 2-3 weeks to have the mould tool manufactured depending on the part's complexity,After we have received final approval by you of the new tool, you can get the parts within 3 days by air.View of factory

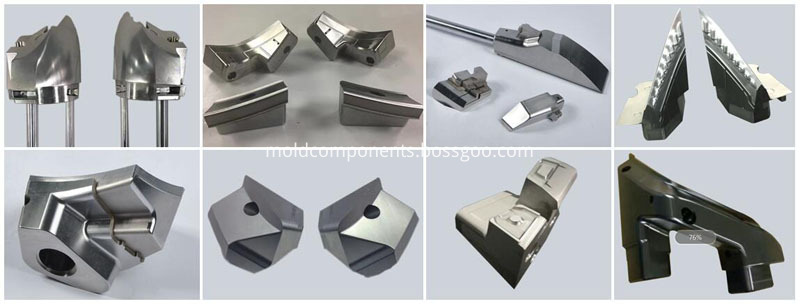

At HZ, we use Hi-speed CNC machine center, Sodick slow-feeding-wire-cut, Sodick mirror EDM and CMM machine checking every process to provide accuracy and precision when making your CNC Machining parts & Mold Components. Our professional and aspiring team of engineers and technicians work in a clean and tidy environment use the advanced equipment, to turn your concepts into reality quickly, accurately and at a great price. You design it and we will make it.

Engineering Design

15 Full Time experienced Tool Designers and has 20 years experience design managerWe are providing Product Design feasibility study from the concept to real part ,tooling optimization, project appraisal and solution proposal.

Advanced equipment

Inspection Center

Injection Molding Slider

Precision Mold Components

CNC Prototype Parts

Mold Parts Project Packaging

Отправьте запрос этому поставщику